CASE STUDY #1

Initial problem

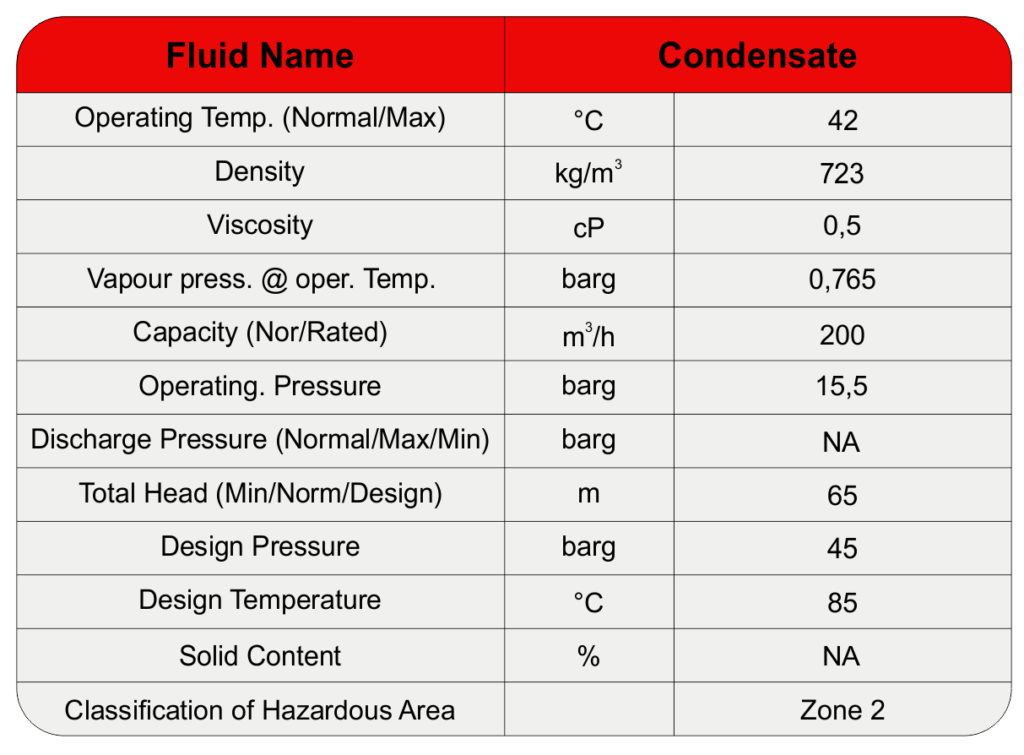

This company is a manufacturer of various types of fiscal measurement systems. For the case in question, they had to manufacture a fiscal flow rate measurement system for an Iranian customer, who was drawing from a 45 bar supplied feeding line and into which they had to feed the measure amount back. They normally used seal pumps for this type of use, however the end customer wanted magnetic drive pumps.

M Pumps solution

We have proposed four magnetic drive centrifugal pumps type CN-MAG-M100-250 according to ISO 5199, in Duplex with manufacture PN100. The duplex was required due to very high system pressure. Additionally the low liquid viscosity has required the use of adequate materials in the construction of the rotating part support bushings (Tungsten Carbide), in order to ensure a longer lifespan of the pump efficiency. The pumps have been supplied on base without motor and the support has been provided for assembly on the customer skids, in order to reduce its testing activities.

These comparative advantages are the prime reasons for clients to consider mag drive pumps against mechanical seal fitted pumps

M Pumps deliver world‐leading expertise in the design, application and manufacture of Magnetically Driven Pumps and associated equipment to API 685, ISO 2858, ANSI B73.3 and ASME for the Oil and Gas, Offshore, Petrochemical, Chemicals, Nuclear, Research Institutes, Pharmaceutical, Electronic and the General industry.