CASE STUDY #4

Initial problem

A plant in CONGO has a propane cooling circuit, which is condensed into a buried tank and put back in service by vertical pumps immersed in the tank.

Unfortunately these pumps collected a lot of dirt from the tank bottom and were constantly clogged and stopped. Maintenance was very complex, since the pumps had to be removed from the tank, which in turn had to be emptied, with prolonged system stop times.

M Pumps solution

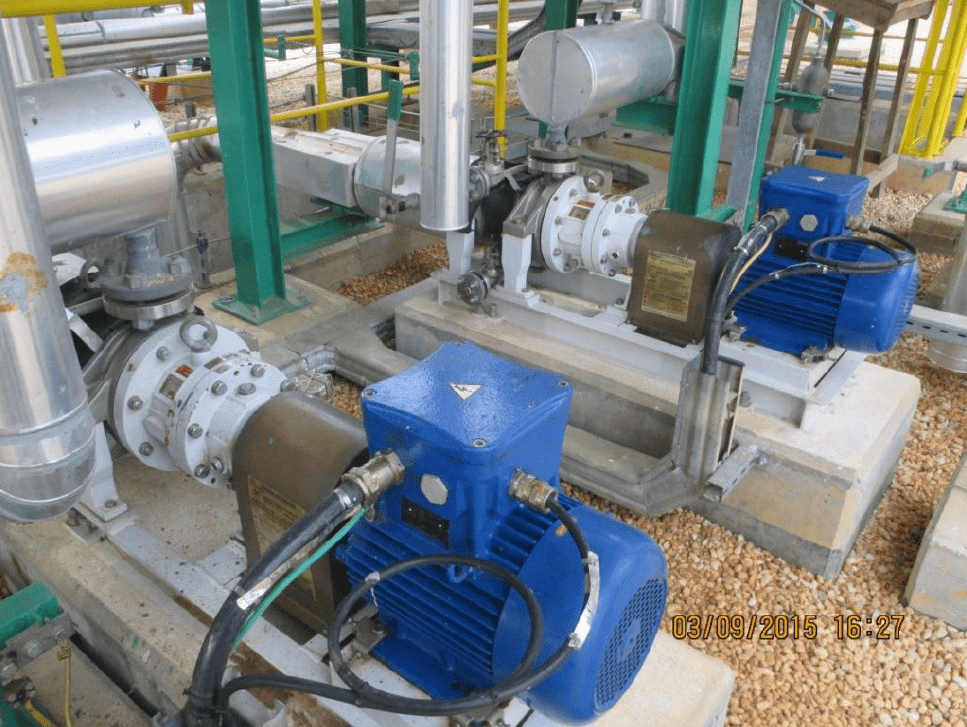

Supply of two self-priming pumps with low NPSH side channels type SC-MAG-M40-2S, installed above the buried tank. Their priming capacity enables the use of a pump external to the tank and therefore the option, in case of fault, of intercepting them through valves and disassembling them without stopping the system (or without emptying the buried tank). Additionally, the option of this type of pumps to be able to pump mixed air – gas fluids up to 50%, enable propane to be pumped at a temperature range very close to evaporation, thus saving on all the equipment required to maintain a low temperature of the piping, allowing for a less expensive system.

These comparative advantages are the prime reasons for clients to consider mag drive pumps against mechanical seal fitted pumps

M Pumps deliver world‐leading expertise in the design, application and manufacture of Magnetically Driven Pumps and associated equipment to API 685, ISO 2858, ANSI B73.3 and ASME for the Oil and Gas, Offshore, Petrochemical, Chemicals, Nuclear, Research Institutes, Pharmaceutical, Electronic and the General industry.