CASE STUDY #09

M Pumps delivers SC MAG‐M30/6S A600# for Project:

The company is a Taiwanese conglomerate with diverse businesses in Petrochemical Processing, Oil Refining, Biotechnology, Fiber and Textile, Electronic Materials, Machinery and Transportation. The company has plants operating across United State and China.

One of the company business units in Taiwan was working on a “confidential” Pilot plant improvement process which required a low flow/high head pump with the ability of safely handling highly flammable and explosive 20% liquid/Gas mixture through injection at suction end. In addition, the vendor was required to deliver the pump set within 6 weeks timeframe upon order confirmation.

After an extensive searched for a suitable pumping solution, the business unit’s request has finally reached M Pumps for technical assistance. After carefully studying the client’s technical specification, M Pumps immediately searched through its range of pumps for a pump which not only handles 20% gas without cavitation and air lock problem but also meeting the low flow/high head process requirement.

Given the unique operating parameters, M Pumps has come up with Side Channel Pumps to meet this specific demanding application:

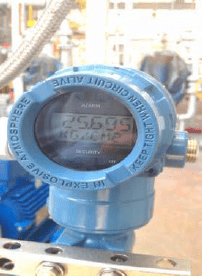

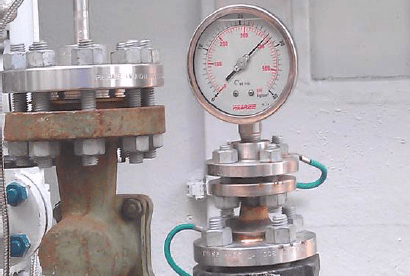

The pump set was delivered to end user’s factory within 5 weeks and was successfully commission at site. As shown on picture, discharge pressure gauge was stable even with 20% gas injection. Pump ran smoothly without unusual noise, heat and vibration.

These comparative advantages are the prime reasons for clients to consider mag. drive pumps against mechanical seal fitted pumps.

M Pumps deliver world‐leading expertise in the design, application and manufacture of Magnetically Driven Pumps and associated equipment to API 685, ISO 2858, ANSI B73.3 and ASME for the Oil and Gas, Offshore, Petrochemical, Chemicals, Nuclear, Research Institutes, Pharmaceutical, Electronic and the General industry.