CASE STUDY #5

Initial problem

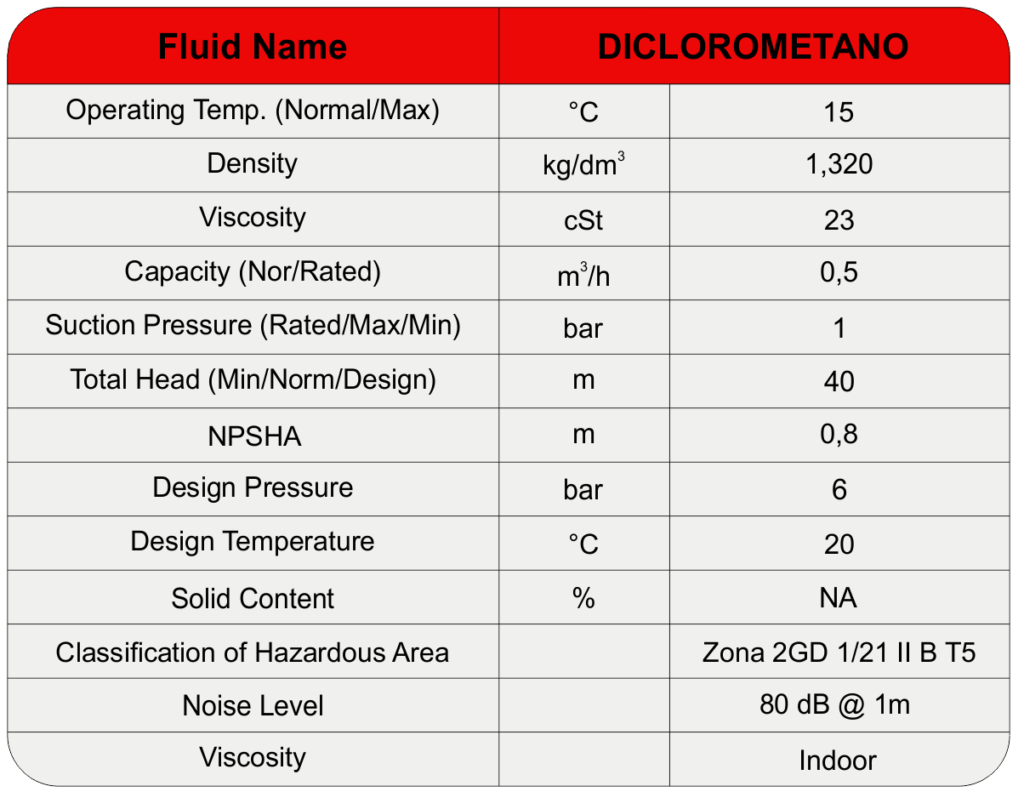

In a plant in Brindisi, there was a problem with magnetic drive turbine pumps of a competing company, used to circulate a solvent (Dichloromethane) that had to be pumped at a temperature below 15°C (evaporation point), in a system not designed for this type of operation (the intake pressure was very low, 1 bar and NPSHa equal to 0.8m) and the pumps required a fairly specific performance ( 0.5m3/h@40m) and it also lacked a cooling and temperature maintaining system. Cavitation occurred in the installed turbine type pumps with frequent breakdowns due to their very high NPSHr.

M Pumps solution

Supply of four centrifugal pumps with turbine type CT-MAG-M9. This type of pumps has two important characteristics: it can operate in a very low flow rates (<1m3/h) field and they have a very low NPSHr (0.4m). These two factors, combines with the introduction of the hybrid glass (low energy dissipation) have resolved this intricate issue. Thanks to the use of the hybrid glass, we were able to generate low heat in the liquid and therefore enable the customer to manage the process temperature control, via the simple use of fresh water cooling, instead of treatments with ammonia or nitrogen.

These comparative advantages are the prime reasons for clients to consider mag drive pumps against mechanical seal fitted pumps

M Pumps deliver world‐leading expertise in the design, application and manufacture of Magnetically Driven Pumps and associated equipment to API 685, ISO 2858, ANSI B73.3 and ASME for the Oil and Gas, Offshore, Petrochemical, Chemicals, Nuclear, Research Institutes, Pharmaceutical, Electronic and the General industry.